OCTG Tubing as per API SPEC 5CT

Engineered for upstream production, our API 5CT tubing (J55–P110 grades) features upset-forged connections and quench-temper heat treatment for superior downhole integrity. L80-13Cr variants resist CO₂ corrosion, while 100% electromagnetic inspection ensures flawless delivery. Global inventory and mill-direct supply minimize rig downtime for operators worldwide.

OCTG Tubing as per API SPEC 5CT

OCTG Tubing as per API SPEC 5CT

| Product | Tubing Pipe, Oil Tubing, API Tubing Well Tubing, Tubing |

| Application | OCTG |

| Pipe Standard | API SPEC 5CT |

| Size | OD: 48.26mm-114.3mm |

| WT: 3.18-16mm | |

| Grade | API 5CT PSL1/PSL2 J55,K55,N80-1,N80-Q, L80-1, L80-9Cr,L80-13Cr,C90, C95, P110, Q125, Super 13Cr, 28Cr, Super 28Cr |

| Length | R1, R2, R3 |

| Connection Type | Plain End, NUE, EUE, premium connection |

| Special Service | Sweet Service, Sour Service, Anti-H2S, NACE MR0175/ISO15156 |

| Accessories: | Pup Joint, Coupling Stock, Coupling, Drill Collar, Crossover |

| Packing: | Thread protectors in Both Ends, Waterproof Paper Wrapped, Two Tags |

Product Advantages

Product Advantages

✓ API Monogram Certified – Manufactured under API Q1 quality system with full compliance to SPEC 5CT (9th Edition)

✓ Comprehensive Grade Range – From J55 to P110, including L80-9Cr/13Cr for sour & corrosive service

✓ 100% Inspection Coverage – Hydrostatic, ultrasonic, and electromagnetic testing ensures zero-defect delivery

✓ Premium Thread Protection – Upset ends (EUE/NUE) with phosphate coating and heavy-duty thread protectors

✓ Global Supply Capability – Mill-direct shipments and regional stocking hubs for rapid delivery

Packaging & Delivery

Packaging & Delivery

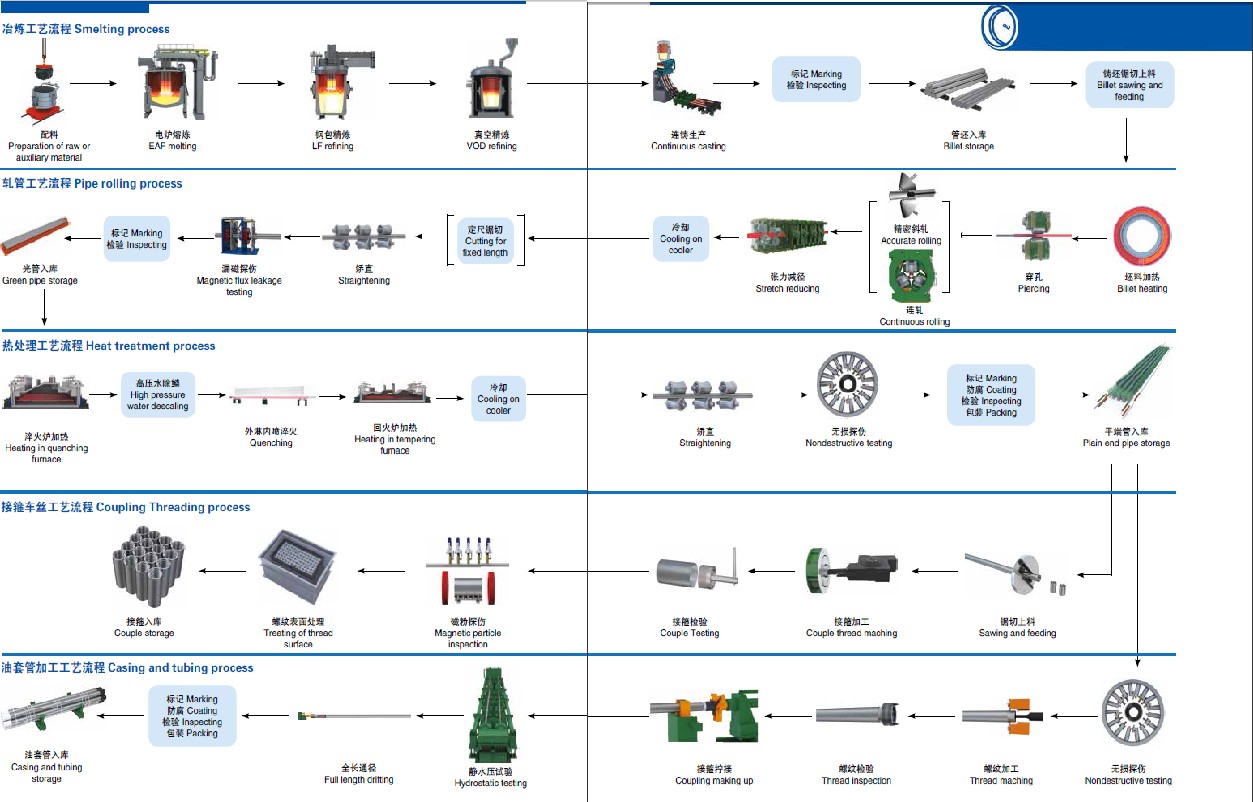

Full-process manufacturing of oil well pipes

Full-process manufacturing of oil well pipes

Leave a message

Scan To Wechat :

Scan To WhatsApp :