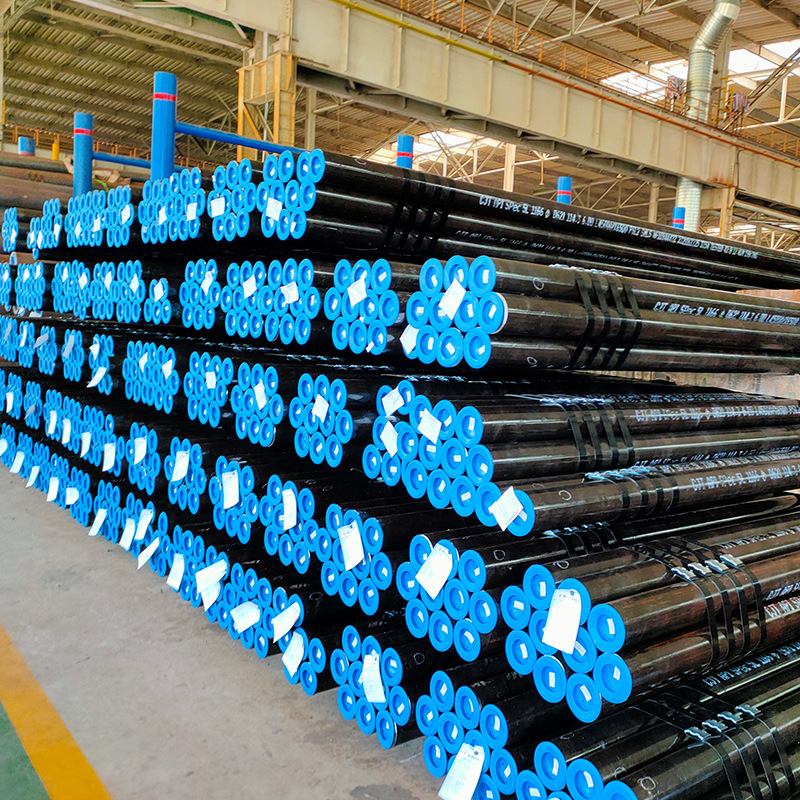

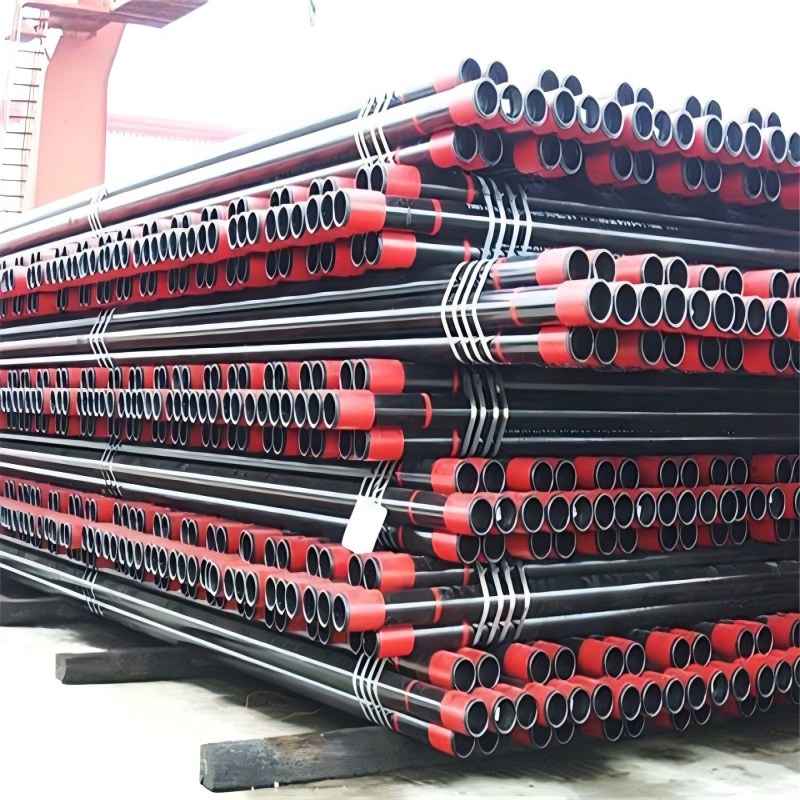

Corrosion Resistant Pipe/ Bar

Product Overview

High-performance corrosion-resistant piping and solid bar stock engineered for aggressive environments, manufactured from stainless steels, nickel alloys, and CRA-clad materials.

Material Grades

Stainless Steel: 304/304L, 316/316L, 310S, 317L, Duplex 2205/2507

Nickel Alloys: Inconel 625/825, Hastelloy C276, Monel 400

Clad Pipe: Carbon steel + 316L/Inconel overlay (3-5mm)

Key Features

Superior resistance to H₂S, CO₂, chlorides, and organic acids

Maintains mechanical integrity at cryogenic to 1100°C

NACE MR0175/ISO 15156 compliance for sour service

Long service life reducing replacement costs

Applications

Offshore oil & gas processing

Chemical/petrochemical refineries

Desalination & marine systems

Pharmaceutical & food processing

Pulp & paper bleaching operations

Specifications

Pipe: ½"–48" OD, SCH 5S–XXS, Seamless & Welded

Bar: ¼"–12" diameter, forged or hot-rolled

Testing: PMI, ferrite measurement, hydrostatic, radiography

Standards: ASTM B444, B705, B423, B163, B165, B167, B637, B446

Read More